Large storage capacity Saving valuable space Environmentally safe Fully automated

Near-zero dust emission and high efficiency

It goes without saying that open storage and transport of ore minerals at mining sites have a huge impact on the surroundings of mining sites. The enclosed Eurosilo system offers a future-proof solution by eliminating heavy dust emission and preventing the pollution of soil and groundwater. The concept of large scale enclosed storage of bulk materials has been proven in the supply chains of major industries around the world, such as the power industry, basic chemical and agri-bulk. Now we are covering new ground with a ground breaking project for the mining industry.

High Capacity Silo Storage

Connecting multiple modalities, from train and truck to bulk carriers requires sufficient storage capacity and suitable input and output rates to keep the mineral ore supply chain flowing in the most efficient way. High Capacity Eurosilos add fully automated operation to that and near-zero dust emission, which is truly ground breaking for the mining industry. Next to that, the vertical storage concept require less than a third space compared to conventional storage with open stock piles.

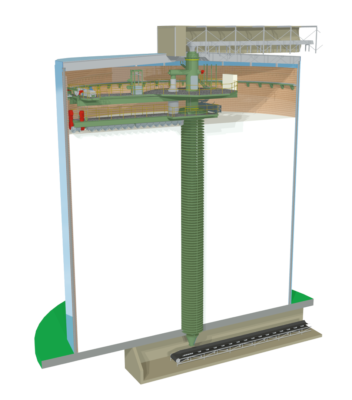

Working principle

The Eurosilo system offers mineral ore storage of up to 60,000 m³ per unit. The material is fed from the top into a chute through which it reaches an auger frame on the surface of the stored mass. Sturdy screw conveyors will then distribute the material in even layers across the surface while the auger frame rotates. Discharge of the mineral ore takes place at the bottom of the silo, while the screw conveyors rotate in reverse to feed the ore into the formed core mass flow in the center of the silo. The output can be suited to feed trucks, trains or conveyor belts.

- Only a third ground space for same volume of mineral ore

- No pollution of air, soil and groundwater

- Maximum logistic control and flexibility

- High availability due to minimal downtime

- Fully automated operation, low operating costs

- Customizable to match transport infrastructure and modalities

Back-of-Port Export Terminal for Newlyn Group

Based on the key features of the Eurosilo, the South African Newlyn Group approached ESI to jointly develop the first-in-world back-of-port manganese terminal in Nqgura. This is because open stockpiling of manganese in the Port of Port Elizabeth and in back-of-port facilities in Markman and Ngqura has created serious issues.

Apart from public health and environmental concerns, the impact of increased volumes of manganese handling on the already burdened infrastructure, roads, traffic, tourism and ecosystems is enormous. It has, for example, resulted in expensive and inefficient watering to reduce dust storms. Therefore, Newlyn was looking for an exceptional solution. Enclosed vertical storage with the Eurosilo system is at the heart of the visionary approach of Newlyn to unlock the huge economic potential in the region and to provide sustainable development.

The project has received overwhelming support from manganese miners and environmental NGOs. Newlyn is planning a similar project elsewhere to address environmental challenges and efficiency matters associated with iron ore and manganese back-of-port operations.