Large storage capacity Saving valuable space Environmentally safe Fully automated

Storing Electric Arc Furnace Dust (EAFD)

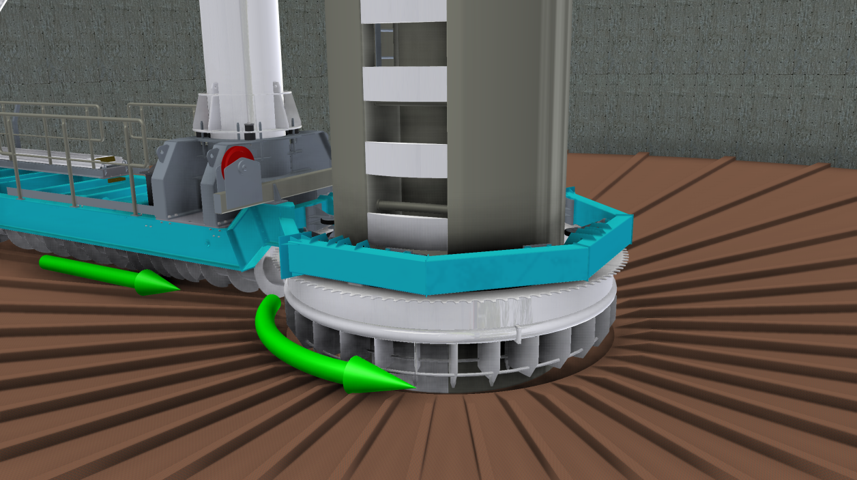

Storing bulk materials with very small particles, such as EAFD or Fly Ash, requires enclosed storage with suitable in- and output systems. For this type of material we have developed the renowned central shutter column system. This system is equipped to store and reclaim Electric Arc Furnace Dust (EAFD) or Fly Ash in a controlled way. These products tend to fluidize during the filling process. By programming the opening and closing of the shutters in the central shutter column, the filling can be handled without the fluidization problem. Reclaiming is done by automated control of the shutters, while the screw conveyors move the EAFD towards the central shutter column. The unique shutter column system is also suited for very fine bulk materials such as Fly Ash or potato starch.

Case Study – EAFD Storage

Zinc Oxide Corporation Vietnam was founded in 2017, based on a partnership between Korea Zinc and ZincOx. Due to the flawless operation since 2012 at the pilot recycling plant of ZincOx in Korea, the Eurosilo system was chosen for a new EAFD recycling plant in Vietnam in 2018. EAFD tends to fluidize and behave like a liquid instead of a solid bulk material when put into motion. For this material we have developed the central shutter column system. Read more about the unique material handling system.

Safe and versatile material handling

A seamless integration into the production environment is largely enhanced by the smallest possible footprint of the Eurosilo. Besides storage and reclaiming in any required quantity, keeping the material safe requires appropriate conditions for materials that are hygroscopic, corrosive or cohesive. Fully enclosed storage in a Eurosilo offers a controlled environment inside and a well-protected environment outside. Flawless filling and reclaiming of materials such as EAFD, Fly Ash and other smaller particle size bulk materials is made possible through our specially designed shutter column system.

Logistic reliability and flexibility

![]()

Contact us