Large storage capacity Saving valuable space Environmentally safe Fully automated

The cleanest storage solution

The increasing demand for energy is rivaled only by the growing concern for the environment, and today’s coal fired thermal power plants have to be equipped with with state-of-the-art clean technology. The Eurosilo system offers the most advanced alternative for open stockpile storage of coal. Enclosed vertical storage in automated silos eliminates environmental drawbacks, such as dust and groundwater pollution, while taking up only a third of the space in comparison with conventional horizontal storage. This makes the Eurosilo the system of choice for new generation power plants and when upgrading older power plants to today’s requirements.

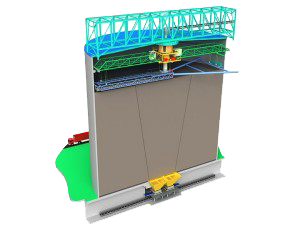

Working principle

The coal is fed into a chute at the top, after which it reaches an auger frame on the coal surface. Two parallel screw conveyors distribute the material over the entire area while the auger frame rotates. The coal is reclaimed at the bottom of the silo, while the screw conveyors rotate in reverse to feed coal into the formed core flow.

- Minimal footprint for large scale storage

- Safest storage method in the market

- No pollution or loss of calorific value

- Maximum logistic control & flexibility

- Minimal operating and maintenance costs

- High availability due to minimal downtime

Leading FGD Gypsum storage system

The mandatory desulfurization of the exhaust of thermal power plants requires accurate handling of the wet and sticky by-product: FGD Gypsum. The FGD Gypsum Eurosilo combines three functions on the smallest possible spatial footprint: dewatering, storage and load-out are all combined in one automated system. Instead of a separate dewatering unit and transport to a storage and load-out facility – requiring operators, power shovels and transport – the Eurosilo offers a complete and cost- saving solution. Compared to conventional silos, the Eurosilo system extends the storage period from just a few days to over three months without any risk of block-ups.

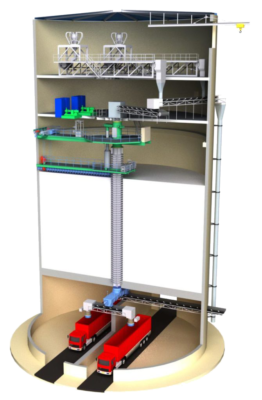

Working principle

In order to eliminate block-ups caused by the poor flow properties of FGD Gypsum, the silo is equipped with a powerful reclamation system in the form of the central slotted column. The stored FGD Gypsum is fed through the slots, formed by the horizontal flat rings, and freely descends down the column. The FGD Gypsum Eurosilo comes with a drainage system at the bottom. This prevents the formation of a sticky layer in the lower regions of the stored mass. In addition, we have developed a system that creates under-pressure in the dewatering system. The complete system will improve your logistic flexibility and preserve the condition of the stored gypsum.

- Minimal footprint for large scale storage

- Safest storage method in the market

- Maximum logistic contro & flexibility

- Minimal operating and maintenance costs

- High availability due to minimal downtime

Fuel Management system maximizes revenue

Your power plant will achieve the highest efficiency rate by burning the optimal coal blend. To prepare the right blends at the right time, our Fuel Management System can be of great help. This software visualizes the different grades of coal in several silos and enables the operators to plan the coal blending in the optimal way. The boiler specifications, the coal characteristics and the measured storage levels are the input data of the Fuel Management System. By reclaiming the respective coal grades from each silo at a controlled and adjustable rate, the right coal blend is achieved.

Case Study – Lünen Coal-Fired Power Plant

The Trianel coal fired power plant in Lünen is with 750MW output, the most efficient and cleanest coal fired power plant in Europe. The coal is unloaded by cranes at the plant and stored dust-free into the two Eurosilos that offer a total capacity of 200,000 tons, enough to operate the plant for about 30 days at full load. Dust emissions are virtually eliminated by using fully enclosed conveyor systems.

Read more about the award winning environmental performance.