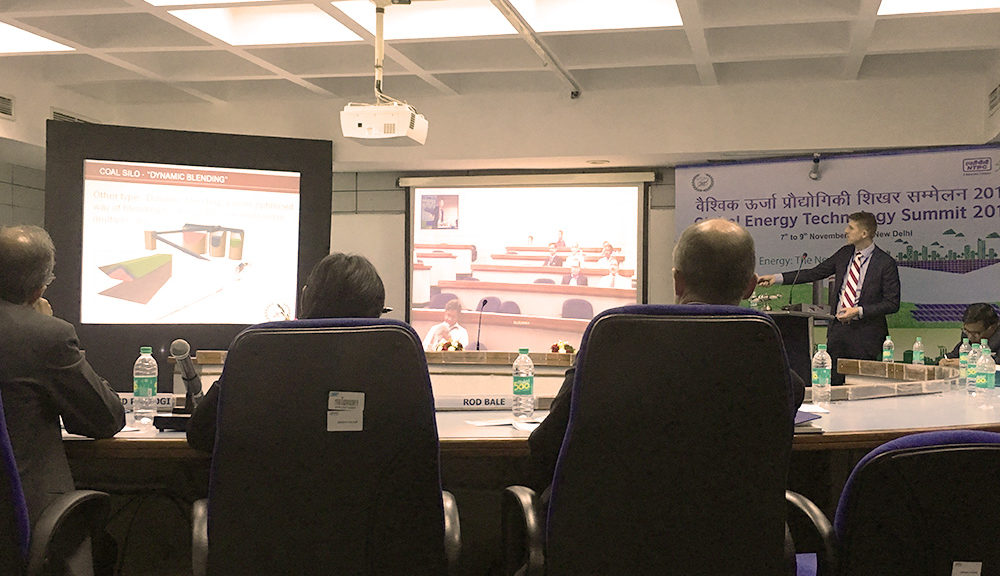

ESI talks about Coal Blending at GETS 2015

ESI Eurosilo was invited as a keynote speaker at the prestigious Global Energy Technology Summit (GETS) 2015 from NTPC to present the technology for coal blending by means of the ESI Fuel Management System (FMS). NTPC is India’s largest energy conglomerate, founded in 1975 to accelerate power development in India.