Case Study – K+S Kali GmbH

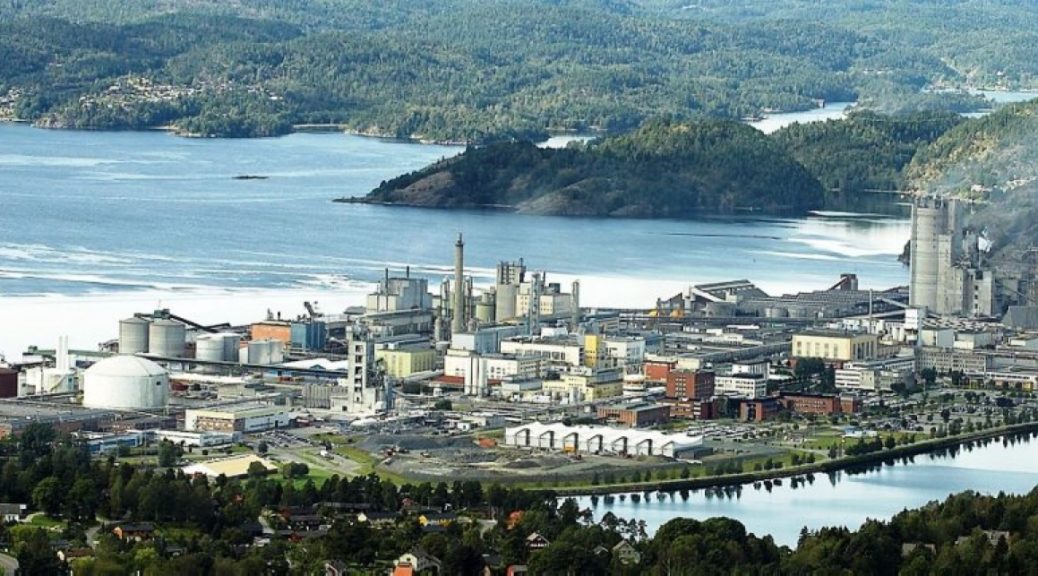

One of the challenges for ESI is to design silo systems that can be operated and maintained under harsh conditions. An outstanding example of this is the Eurosilo system that was supplied to K+S KALI GmbH at their Sigmundshall plant…