Moving forward with R&D

Now that the Eurosilo has become a renowned solution in number of industries, the concept of highly automated space saving vertical storage is drawing attention from different parties in other industries. This is why last year was decisive in kicking off our long term strategy with ground breaking R&D projects, headed by Sjaak van Hurck, Technical Director at ESI.

Change and transformation

The impact of global developments such as growing population, climate change and increasingly scarce natural resources is driving change and transformation in major industries. This is impacting regional regulations as well as supply chains, business models and technological developments. At ESI, Sjaak van Hurck is leading R&D projects that arise from a faster changing world: “The increased demand of steel has now led to a race for manganese ore in the mining industry. So we are asked to study the possibility of the Eurosilo for large scale storage of ore.”

Testing with ore

Developing long term solutions means ensuring safety, functionality and economic value in the future. This requires research today to study the yield of mechanical components as well as the required power to handle specific bulk materials. Sjaak: “Since we are in the business of large scale bulk storage, the consequences of failure are huge. In order to predict how the screw conveyors inside the silo will hold up with ore, which is 2,5 times heavier than coal, we are now testing abrasion resistance of different materials. We have set up a special testing environment, simply because there is no facility that has verified data that we can use. So far, we can see promising patterns of different materials under constant impact with the ore.”

Investigating soybean storage

“The increased demand for soybeans causes producers to buffer large quantities of stock. So what would happen if you store these in a Eurosilo instead of acres full of sheds? The much smaller footprint enables large scale storage at places where space consuming sheds simply aren’t possible. Producers are now paying for barges at harbors for this reason. When shipped to a storage facility, soybeans are dry, relatively light and easy to handle, making the Eurosilo an interesting alternative. We already built soybean silos in Denmark in the ‘70s and we are now investigating optimization of the design, amongst others in terms of larger capacity, to bring it up to ’22 standards”, says Sjaak.

New product development

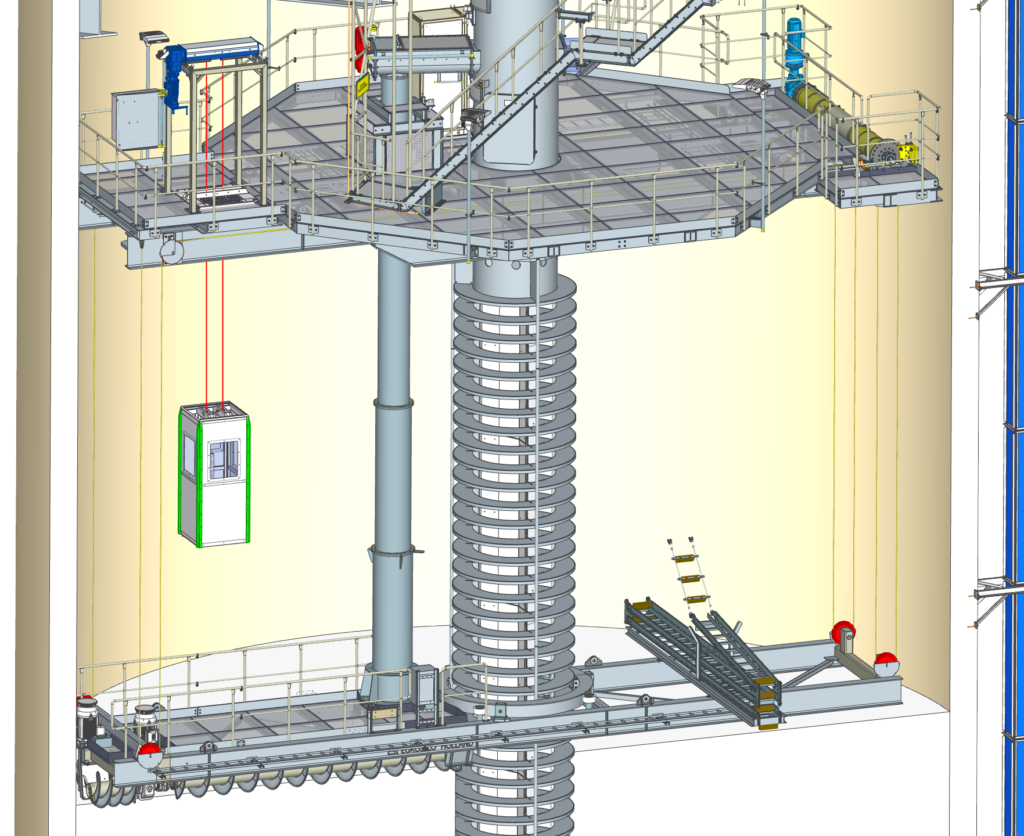

Next to basic research, R&D at ESI has also developed a new product that is already available for operation: the propriety ESI Silo Descend System (SDS). Due to the ATEX security, the conventional system was not reliable enough, making it difficult for maintenance crews to reach the lower equipment of the silo mechanism. Although the new ESI SDS offers distinct advantages, Sjaak was pleasantly surprised by the fast adoption of their own solution: “It has ATEX certification, it is more stable while being suspended freely under the bridge and it is reliable. But 7 units sold and more to follow, really exceeds our expectations. Looking at the current projects, I’m sure the scope of R&D will increase in the new year!”