DETECT AND PREVENT UNFAVORABLE CONDITIONS IN DE STORED MASS

The innovative storage solution

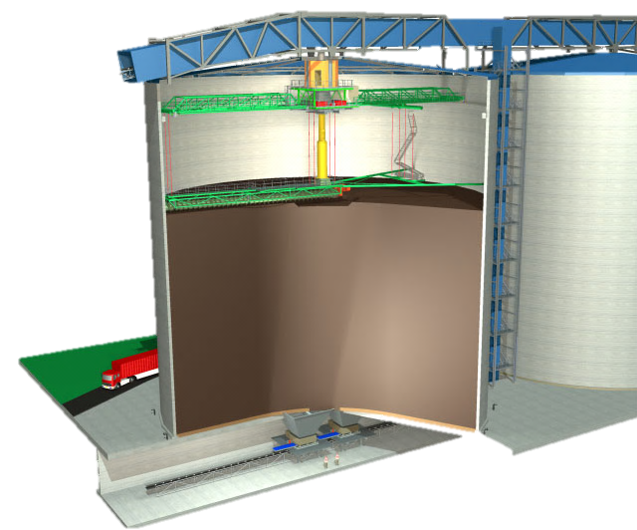

Conventional open-air storage requires sufficient space at your plant site and leads to costly environmental drawbacks and loss of calorific value. Enclosed storage in a highly automated Eurosilo solves all these problems at the smallest possible footprint. The system offers the safest storage in the market for up to 200,000 m³. The coal is fed from the top into a chute through which it reaches an auger frame on the coal surface. Two parallel screw conveyors distribute the material over the entire area while the auger frame rotates. Reclaiming is done at the bottom of the silo, while the screw conveyors rotate in reverse to feed coal into the formed core flow.

Fuel Management system maximizes revenue

Your power plant will achieve the highest efficiency rate by burning the optimal coal blend. To prepare the right blends at the right time, our Fuel Management System can be of great help. This software visualizes the different grades of coal in several silos and enables the operators to plan the coal blending in the optimal way. The boiler specifications, the coal characteristics and the measured storage levels are the input data of the Fuel Management System. By reclaiming the respective coal grades from each silo at a controlled and adjustable rate, the right coal blend is achieved.

Lifecycle assessment with EMA

To ensure long-term return on investment, it is vital to achieve cost-effective compliance with environmental regulations and self-imposed policies. Environmental Management Accounting (EMA) integrates environmental, operational and maintenance issues into the financial analysis. An integrated lifecycle assessment, as recognized by the European Community, offers a complete evaluation. Following this approach, the investment in Eurosilo systems comes with a payback period of only 10 to 15 years.

- Minimal footprint for large scale storage

- Safest storage method in the market

- No pollution, nor loss of calorific value

- Maximum logistic control & flexibility

- Minimal operating and maintenance costs

- High availability due to minimal downtime

Introduction to coal storage in a Eurosilo at the coal fired power plant in Lünen Germany

A short introduction to the Eurosilo advanced storage solutions in the densely populated area at the ultrasupercritical power plant at Lünen in Germany. The solution is a space saving design and the future proof solution for coal storage.

We’re happy to provide more detailed information.

Downloads