Supporting Weibull Silos Around the World

With a similar working principle as the Eurosilo system, ESI is the partner for more and more Weibull owners to keep their silos up and running, since Weibull directed its activities to other markets in the mid-1990s. Originally, the Weibull silos were developed for the Swedish beet sugar industry. The first silo, built in 1933, was designed by Nils Weibull, a civil engineer. Since then, the silo system was modified for other applications such as starch, lime, and fly ash. The main application however still is white sugar.

Wide Adoption

The Weibull silos offered an effective alternative to ground-level warehouses in terms of space requirements, handling costs, and control of temperature and humidity. This is why the use of Weibull silos quickly spread across sugar producing regions in Europe and the USA. With infeed from the top, a distribution frame to create layers inside the silo, and a mechanical outfeed system, the silos are also suitable for other materials. Like the Eurosilo, the enclosed system is also used for fly ash, potato starch, calcium nitrate and coal in the power industry.

ESI Support for Weibull Systems

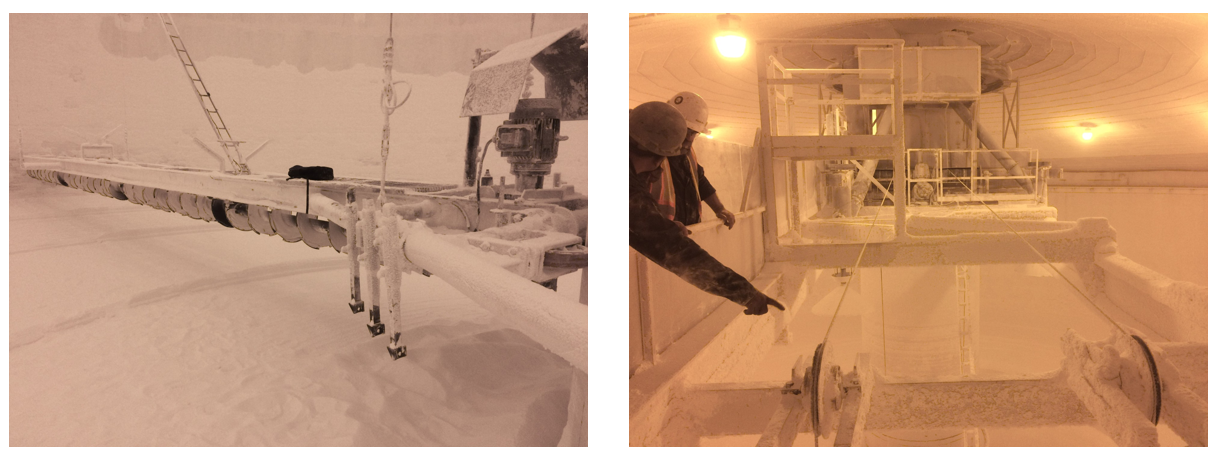

With Weibull pioneering at the beginning of the last century, more silos have passed their economical lifespan. This is why facility owners now turn to ESI for inspections and support of their Weibulls. As stated in our Sugar Silo Paper, these systems require increasingly more maintenance and cause undesired interruptions. Often they don’t meet today’s safety standards and environmental regulations anymore. In addition to inspection and modernisation for leading agribulk producers, such as Amalgamated Sugar Co, Nordic Sugar, Lyckeby, and Emsland Stärke, ESI also delivered modernisation projects for cement producers such as Rohrdorfer Zement and Heidelberger Zement.

Continuity Strategies

Typically, we see three continuity strategies in our Weibull-projects. The most common is the repair or replacement of obsolete components. Thanks to our extensive network of suppliers, we can provide alternatives for parts from manufacturers that no longer exist. Another strategy is conversion, using state-of-the-art Eurosilo infeed, storage, and outfeed mechanisms. In this case, the silo structure remains intact while the material handling system is replaced. A third strategy can be to design and build a new Eurosilo, based on the findings of detailed feasibility studies.

More Information

ESI is currently engaged in projects for Weibull silos in Europe as well as in the USA. For more information about our worldwide services, please contact us through service@eurosilo.com or leave a message via the contact form. We’ll be happy to provide you with any information you need.