Producing white sugar from sugar beets is one of the primary industries in Europe. As with other agricultural industries, consolidation and optimisation of the production facilities are the main strategies for sugar producers. The focus on production leads to less attention for storage. As a result, many outdated and inefficient sugar silos are still in operation. Maintenance issues have become a major concern, while European production volumes increased tenfold compared to the silo storage capacity. It is time to catch up by using the Eurosilo System to secure both operational and strategic advantages.

Changing market conditions

As one of the oldest agricultural processing industries, many sugar storage facilities date back to the 1980s or even the 1960s. In the meantime, technology has advanced a lot, offering automation and improved efficiency, while original silo manufacturers such as Weibull, ABR, and Spaans, have left the market. This leaves it up to the resourcefulness of technical departments to keep these silos up and running. Additionally, the regulations for the production environment have become stricter, particularly regarding Health & Safety and CO2 emissions. The Eurosilo system is based on a similar working principle as the old Weibull systems, only it has constantly evolved to meet the latest standards.

Learn more and download the Eurosilo Sugar Storage Paper.

Maintenance inefficiency

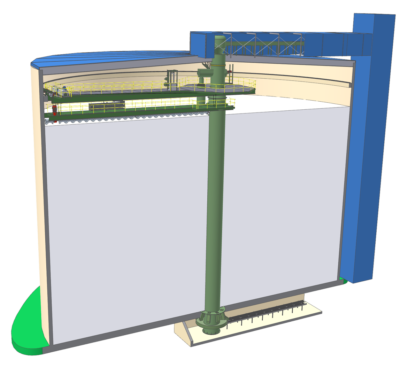

Maintaining the older silos is one of the main concerns due to the commonly used system with numerous hatches in the silo floor to reclaim the stored sugar. This requires a mobile conveyer belt in the foundation under the silo to move to sometimes over a hundred spots to capture the sugar that falls through the opened hatches. Obviously, such a system is more liable to defects. The biggest issue however, is the silo clean-up with a bottom screw that rests in the stored sugar. The constant pressure of the stored mass often causes the bottom screw to malfunction. As a result, maintenance workers have to enter the silo for repairs as well as to manually remove remaining sugar.

Futureproofing Sugar Plants

One of the steadily growing regions for beet sugar production is Poland. Jacek Kucharski from our Eurosilo agent Ricco International: “There is a huge potential for the Eurosilo system here because the total silo capacity is about 650 thousand to 750 thousand tonnes, whereas the production soared to 2.5 million tonnes per year. A key issue is the lack of suitable silo technology that reduces the problem of maintenance and meets all requirements, such as the Eurosilo system. Investing in automated, large-scale sugar storage provides strategic advantage during price fluctuations of the agricultural crops. At the same time, operational costs will decrease significantly, resulting in a short payback period!”

Conversion and updating

When considering the current assets for sugar storage in the European market, constructing new silos is not necessarily the first step. As Jean-Marie Oheix from LS Process explains: “The main strategy in France, one of the largest regions for production of sugar, will be to upgrade or revamp the existing storage facilities. Therefore it is a big advantage that ESI handles Weibull and Spaans silos with conversion, maintenance and upgrade. In case of a replacement, a brand new Eurosilo guarantees the producers 30 years of hassle free, reliable and low maintenance storage.”

Download our Sugar Silo Paper

To help you get a better understanding of the Eurosilo system and the complete configuration to meet ATEX and food regulations, as well as care free maintenance and fully controlled conditioning of sugar, we prepared a concise paper with more detailed information. Learn more and download the Eurosilo Sugar Storage Paper now!