Sugar Storage

- Large storage capacity

- Saving valuable space

- Environmentally safe

- Fully automated

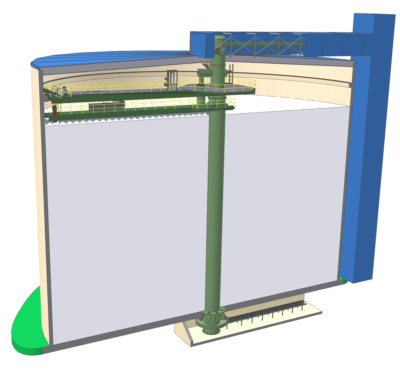

Sugar Storage with the State-of-the-Art Eurosilo

For long-term sugar storage, ESI provides silos specifically designed to maintain optimal storage conditions, including precise moisture and temperature control. This approach ensures that sugar remains fresh, dry, and free from contamination throughout its storage period.

Improved efficiency

Each Eurosilo integrates automated loading and unloading systems to reduce labour costs and minimize product loss. The auger system on top of the sugar employs a layer-by-layer filling method, which ensures uniform distribution throughout the silo and improves moisture control by preventing segregation. The unique design allows for efficient cleanup without additional labour, in contrast to alternative systems that often require labour-intensive complete silo cleanup.

Whitepaper Sugar Silo Storage

To help you get a better understanding of the Eurosilo system and the complete configuration to meet ATEX and food regulations, as well as care free maintenance and fully controlled conditioning of sugar, we prepared a concise paper with more detailed information. Learn more and download the free Eurosilo Sugar Storage Paper.

High safety, low maintenance

The Eurosilo is constructed from high-grade, food-safe materials. Maintenance is simplified by providing easy access to all critical components. Additionally, the use of a single outlet system facilitates an efficient civil design, reducing overall civil costs. Adherence to safety standards such as ATEX and NFPA, as well as integrated monitoring systems, further enhances operational safety and reliability.

- Long term storage of sugar, due to optimal conditioning

- High capacity storage up to 100.000 ton storage

- Optimal homogenization due to layer by layer filling pattern

- Explosion proof design according to ATEX / NFPA standards

- Reduction of labour costs due to fully automated operation

- Complete clean up by means of fully automated system