Different systems, different materials

- Large storage capacity

- Saving valuable space

- Environmentally safe

- Fully automated

Four systems for a wide range of bulk materials

To reliably handle a range of bulk materials we developed four Eurosilo systems: the mass flow, slotted column, hatched column, and window column system. Each of these systems is suitable to handle specific types of bulk materials, from cohesive and hygroscopic to fine powders or combustible. All to ensure controlled flow, safe handling, and reliable operation at your production site. You’re welcome to explore the application and working principle of the system that suites your requirements. For more detailed information you can always contact us.

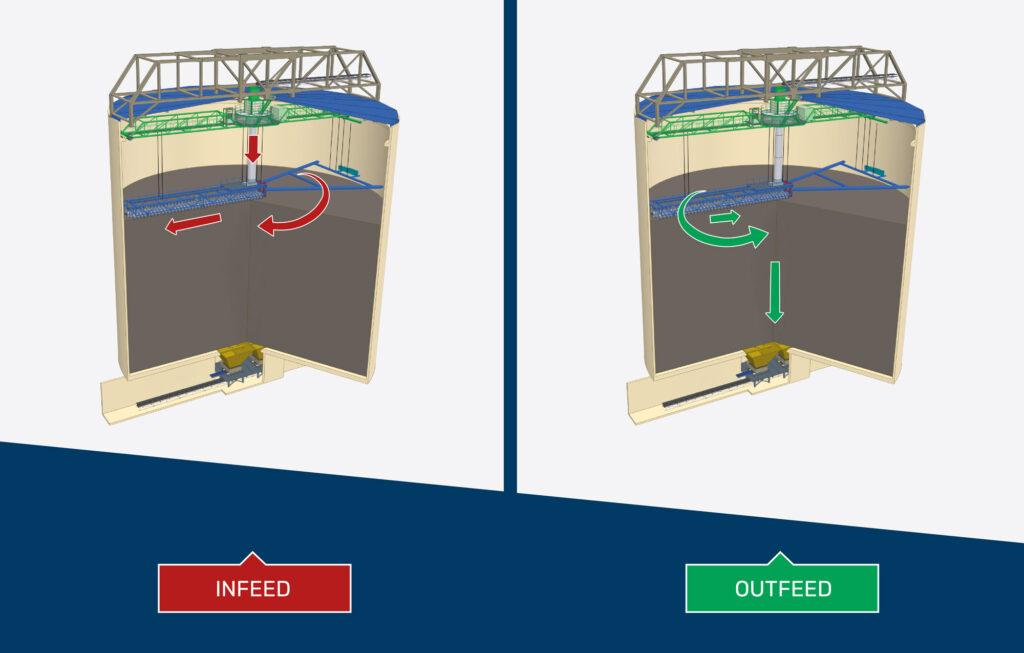

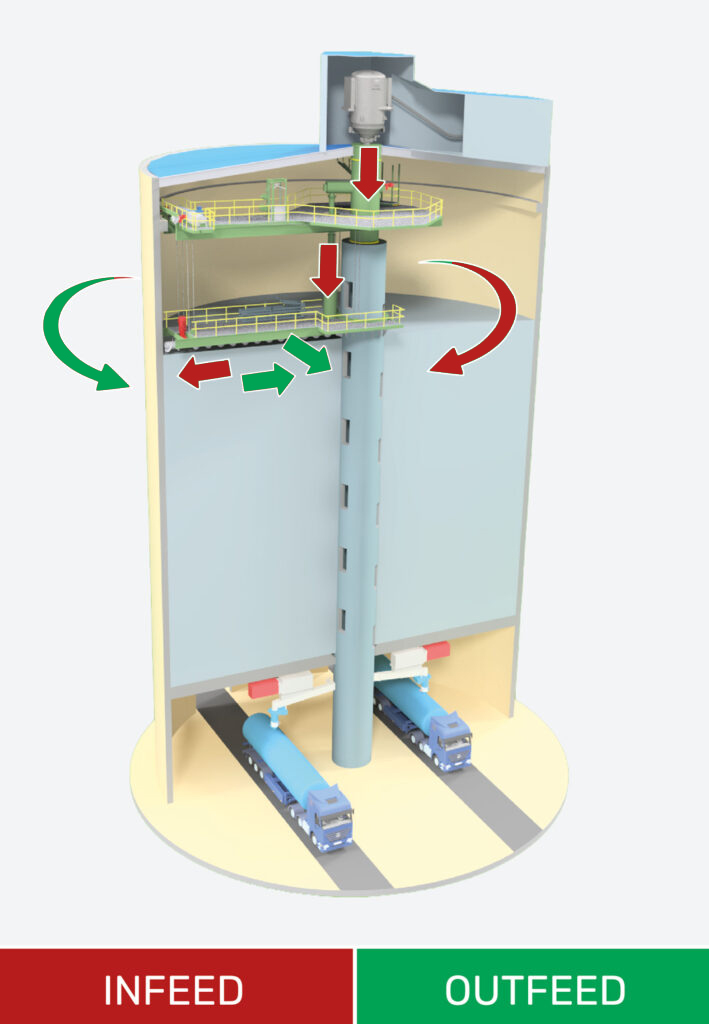

Mass flow system

Free flowing bulk materials

The Eurosilo Mass Flow System is the ideal solution for products with sufficient flowability to be extracted by gravity, supported by vibration to induce a controlled core flow. With storage capacities of up to 100,000 m³ per unit, the fully enclosed Eurosilo keeps products such as calcium nitrate, coal, and petcoke in good condition, while protecting the environment. The small footprint relative to the stored volume makes the Eurosilo Mass Flow System particularly suitable for expansion within limited space at existing plant sites.

Working principle

The bulk material is fed from the top of the silo through a telescopic chute and reaches the distributing frame on the surface of the stored material. The distributing frame, equipped with screw conveyors, spreads the bulk material evenly over the entire silo cross-section, building the stock layer by layer. Reclaiming is performed by withdrawing the bulk material from the central hoppers in the silo bottom, thereby inducing a controlled core flow. The distribution frame feeds the material into the formed central flow channel, ensuring stable and reliable discharge.

Key features

- Minimal footprint for large scale storage

- Fully automated operation resulting in low operating cost

- Complete discharge of silo content

- High availability and low maintenance costs

- No pollution or loss of material characteristics

- Safest storage method in the market

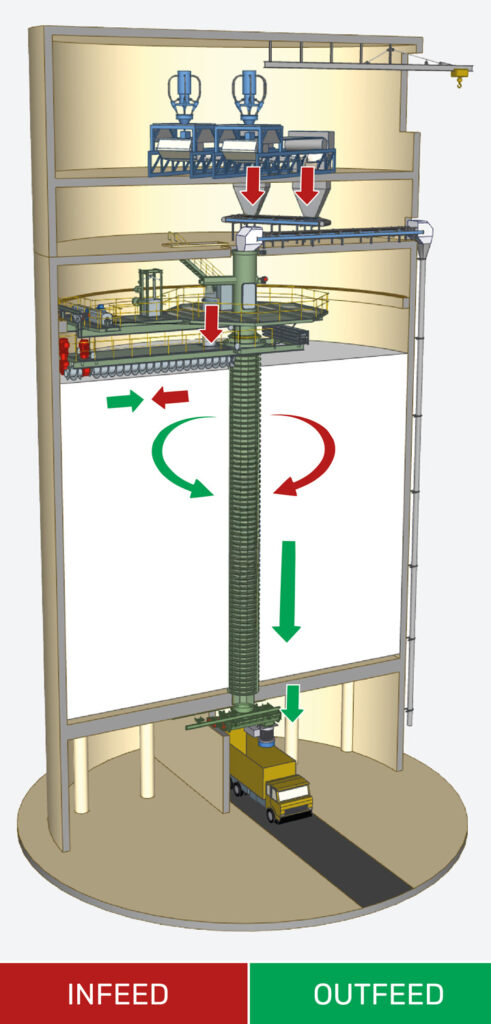

Slotted Column

Optimized for cohesive material

The Slotted Column System is a proven solution for cohesive or hygroscopic bulk materials such as FGD Gypsum or Ammonium Sulphate. In case of FGD Gypsum, the Eurosilo can combine three functions with dewatering on top, storage in the middle and load out underneath. Instead of separate dewatering and transport to a storage and load out facility, there is just one cost-saving, reliable solution. FGD gypsum Eurosilos can be equipped with a drainage system to prevent the formation of a sludge layer. Over 80 FGD gypsum silos, and counting, are supplied at plants around the world.

Working principle

To prevent blockages, the slotted central column is designed for the smooth reclaiming of cohesive and consolidating materials. Horizontal screw conveyors transport the bulk material towards and through the slots, formed by the horizontal flat rings. This way it can flow freely downwards through the open central column. This reclaiming system extends the storage period by up to several months without any issues.

Key features

- Uninterrupted reclaim of cohesive material

- Smallest footprint for efficient storage

- Longest storage period for FGD Gyspum

- Controlled atmosphere for hygroscopic materials

- High automation minimizes operating costs

- Complying with severe environmental regulations

Hatched Column

Control of very fine particles

Bulk materials with a very small particle size, such as potato starch, fly ash or electric arc furnace dust (EAFD), tend to fluidize when put into motion. This is when the material changes into a liquid state, making effective bulk handling challenging. Enclosed storage combined with the specially designed hatched column enables you to handle fine particle bulk material in a controlled way. Since its introduction in the 1960s, the hatched column system performs successfully at starch or sugar factories in the food industry and at recycling companies in the metal industry.

Working principle

The bulk material is fed into the silo from the top via a filling screw conveyor and loading chute. During the filling process, the distribution frame evenly spreads the material across the silo surface, ensuring uniform filling. For reclaiming, the material is guided toward the centre by the distribution frame and ring conveyor. By opening the hatches at the surface of the stored bulk material, it can flow into the central reclaim column. The height position of the suspended distribution frame controls the opening and closing of the corresponding hatches, enabling precise and controlled discharge.

Key features

- Controlled handling of fluidizing bulk materials

- Smallest footprint for efficient storage

- Safe long term storage of bulk solids

- High automation minimizes operating costs

- Complying with severe environmental regulations

- Maximum logistic control and flexibility

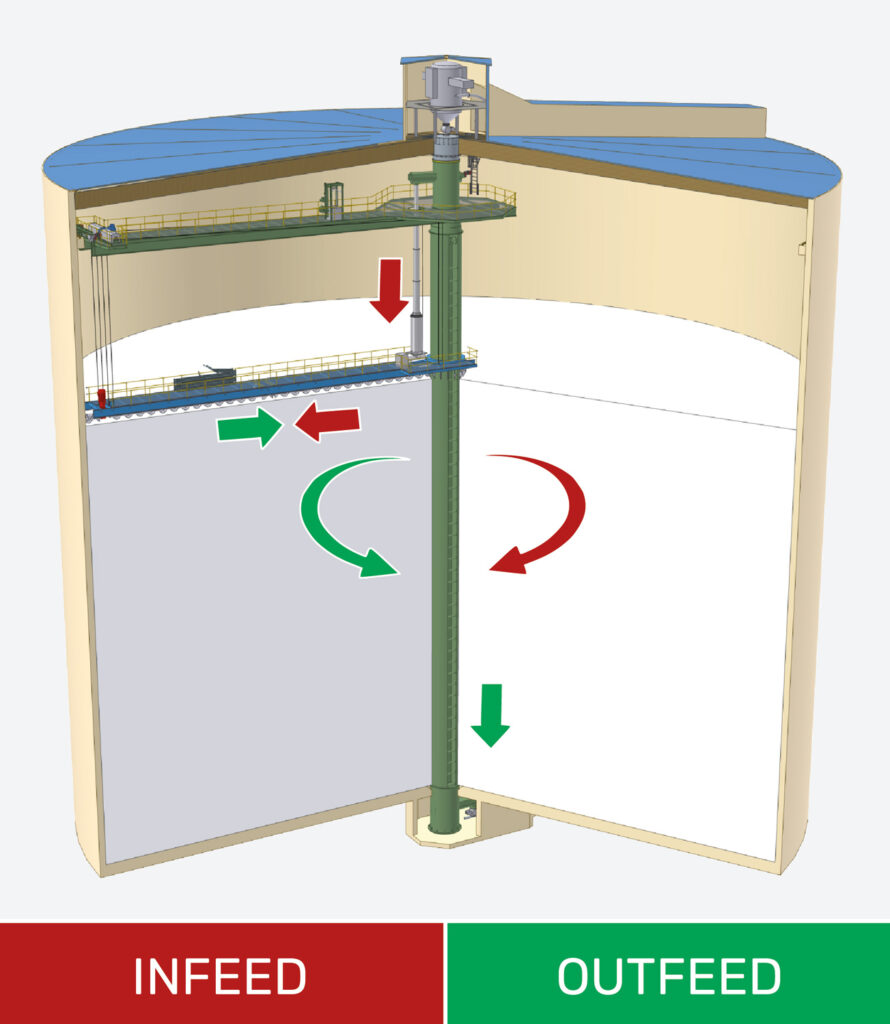

Window Column

Large capacity, long term storage

The Window Column System is specifically developed for the storage of large volumes—up to 100,000 tonnes—of fine bulk materials such as cement and fly ash. These materials exhibit complex behaviour: they fluidize when in motion, behave like powder when at rest, and can become solid under sustained pressure. The Window Column System is engineered to control these material characteristics while offering a significantly larger storage capacity than conventional silo systems. The open channel within the central column eliminates the need for full mass recirculation. As a result, cement and fly ash can be stored safely for extended periods—up to several months—without any operational or material quality issues.

Working principle

The bulk material is fed into the silo via a filling screw conveyor and discharged through a telescopic chute onto the storage surface. The distribution frame spreads the material evenly in controlled layers across the surface of the bulk material. When reclaiming starts, the screw conveyor and ring conveyor transport the bulk material toward the centre column, where it enters through fixed openings. The bottom of the column is aerated, inducing a core flow pattern within the column. By reclaiming material from the bottom of the column, a continuous and stable flow of bulk material is achieved. The distribution frame is automatically lowered in a precise layer-by-layer sequence, ensuring controlled reclaiming and consistent material flow.

Key features

- Controlled handling of fluidizing bulk materials

- Large capacity storage in a single silo system

- No recirculation requirements

- High infeed and outfeed rates

- Fully automated filling and reclaiming

- Complete reclaiming of stored bulk material

- Smallest footprint for large scale storage

Contact us

Feel free to reach out to us with any questions, comments, or feedback. Fill out our contact form, and we’ll get back to you as soon as possible. Your inquiries are important to us, and we look forward to assisting you.