Agribulk Industry

- Large storage capacity

- Saving valuable space

- Environmentally safe

- Fully automated

Strategic advantage in the Food Supply Chain

How can seasonal crops be aligned with continuous production and fluctuating market demand? This question, which led to the development of the Eurosilo over 50 years ago, remains a critical challenge for today’s agribulk producers. Producers must assess their storage requirements, balancing short-term seasonal production with the need for long-term growth. The Eurosilo offers a strategic, fully enclosed, and space-efficient vertical storage solution, ensuring that agribulk products like potato starch, sugar, and soybean remain readily available in the most profitable and cost-effective way.

Proven technology

The Eurosilo is a popular solution for storing large volumes of bulk solids, such as potato starch, soybean, and sugar. Engineered specifically for agricultural bulk storage, these silos create optimal conditions to preserve the quality of materials, even over extended periods. The use of stainless steel, moisture-free environments, and the removal of any residue inside the silo effectively prevent the degradation of perishable goods. Furthermore, the risk of dust explosions is greatly minimized by adhering to the latest ATEX or NFPA standards. Safety features are reinforced through advanced detection systems and integrated fire extinguishing equipment. As a result, the Eurosilo has become the preferred storage system for leading potato starch producers in Europe and Asia.

Eurosilo versus conventional storage

There are two main methods for storing potato starch: stacking big bags in warehouses or using fully automated silo systems. Big bag storage involves lower capital expenditure (CapEx) due to minimal infrastructure needs, but it leads to higher operational expenses (OpEx) driven by labor and material handling equipment such as trucks and forklifts. In contrast, the Eurosilo system requires a higher upfront investment but significantly lowers operational costs due to its fully automated design. Over its lifespan of 30+ years, the return on investment strongly favors the Eurosilo solution. Beyond the financial benefits, the Eurosilo also requires less space and reduces product deterioration during long-term storage wich are key advantages for today’s producers.

For soybeans, the common storage method is endless rows of sheds on huge industrial estates. The Eurosilo system can store the same volume of soybeans at less than a third of the ground space needed for shed storage. Enclosed Eurosilo storage offers a controlled environment to keep humidity at a minimum level, automated infeed and outfeed.

When it comes to sugar storage, large silos with multiple outlets are commonly used, necessitating manual labor to extract materials from each outlet. The automated Eurosilo system significantly reduces the manual labor required during the discharge process, streamlining operations and increasing efficiency.

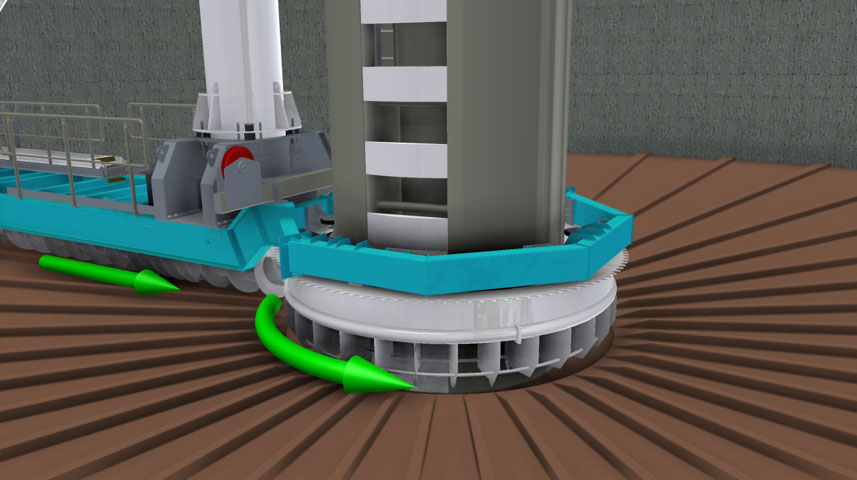

Working principle

To handle dusty products, ESI Eurosilo has developed the innovative Hatched Column System. This system is designed for storing various materials, including potato starch, fly ash, and electric arc furnace dust (EAFD). These products tend to fluidize during the filling process, presenting unique challenges. Additionally, the weight of the stored mass can lead to increased compaction over time. By programming the opening and closing of the shutters in the central column, the filling and reclaiming can be handled in a controlled manner.

The world’s largest potato starch storage in Karup

With the successful installation of the second Eurosilo in Karup, one of the production sites of KMC, the world’s largest potato starch storage facility has been realized. With more than 60 potato-based products and over 90% worldwide export of its production, KMC is a leading producer, owned by starch potato farmers.

The automated 88.500 m3 potato starch silo in Karup is the latest of no less than five Eurosilos that were built for KMC at different production sites in the last 7 years. The huge storage capacity enables KMC to bridge the gap between seasonal production and changing market situations. The key to this advantage is large volumes. This requires proven technology to safely store potato starch for an extended period of time. Fully enclosed storage in a Eurosilo keeps the potato starch in perfect moisture free condition with wooden cladding on the concrete silo wall. The automated infeed and output is handled by the Eurosilo system, using the propriety central shutter column and rotating screw conveyors to move the potato starch.

Most importantly, the vertical storage concept reduces the required ground space to about one third compared to big bag storage in multiple warehouses. At existing production sites, such as with KMC, this is vital for expansion.

Contact us

Feel free to reach out to us with any questions, comments, or feedback. Fill out our contact form, and we’ll get back to you as soon as possible. Your inquiries are important to us, and we look forward to assisting you.