Prozessindustrie

- Große Speicherkapazität

- Sparen Sie wertvollen Platz

- Umweltverträglich

- Vollständig automatisiert

Kontrollierte Lagerung für eine ununterbrochene Produktion

Das Eurosilo-System bietet große Vorteile für die spezifischen Anforderungen von chemischen Prozessanlagen. Um eine ununterbrochene Produktion zu gewährleisten, ist eine sichere und zuverlässige Lagerung von Kalziumnitrat, Ammoniumsulfat, Kochsalz oder Borax von entscheidender Bedeutung, um die logistischen Intervalle für den Versand an die Kunden einzuhalten. Dies erfordert nicht nur die Lagerung und Ausgabe in jeder gewünschten Menge, sondern auch geeignete Lagerbedingungen, um die korrosiven, hygroskopischen oder kohäsiven Eigenschaften der Grundchemikalien zu handhaben. Die geschlossene und automatisierte Lagerung im platzsparenden Eurosilos hält Basischemikalien und Mineralien sicher und leicht verfügbar für den nächsten Schritt in der Lieferkette.

Sicherer und vielseitiger Materialtransport

Um der hygroskopischen Natur von Grundchemikalien gerecht zu werden, sind unsere geschlossenen Lagerlösungen so konzipiert, dass der Feuchtigkeitsgehalt auf einem absoluten Minimum gehalten wird. Die Verwendung von nicht-korrosiven Materialien im Inneren schützt die Lagereinrichtung vor Schäden oder Leckagen aufgrund des korrosiven Inhalts. Auf diese Weise gewährleistet das geschlossene Eurosilo-System feuchtigkeitsfreie Bedingungen im Inneren und Umweltsicherheit im Außenbereich. Eine einwandfreie Befüllung und Rückgewinnung des nicht frei fließenden Schüttguts wird durch die speziell entworfene Schlitzsäule oder die automatische Verschlusssäule ermöglicht.

Zuverlässig und platzsparend

Mit jahrzehntelanger Erfahrung in der chemischen und mineralischen Grundstoffindustrie ist der Eurosilo so gebaut, dass er auf lange Sicht zuverlässig ist. Da sich unsere Lagereinrichtungen nahtlos in jede Produktionsumgebung einfügen müssen, sind sie kompakt, robust und zuverlässig konzipiert. Mit der kleinstmöglichen Grundfläche bietet der Eurosilo eine Lagerfläche von bis zu 100.000 m3 und kann auf Ihre Wünsche und Bedürfnisse zugeschnitten werden.

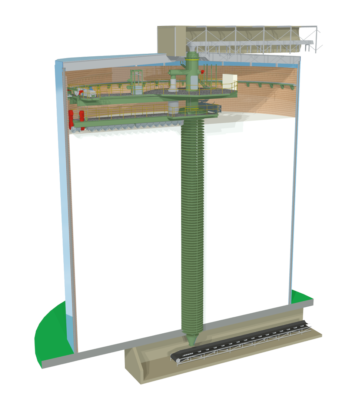

Funktionsprinzip: Schlitzsäule

Um Verstopfungen zu vermeiden, wurde die geschlitzte Mittelsäule für die reibungslose Entnahme von Schüttgut entwickelt. Das Schüttgut wird von der Oberseite des Silos in eine Teleskoprutsche geleitet, über die es den rotierenden Verteilerrahmen auf der Oberfläche der gelagerten Masse erreicht. Horizontale Förderschnecken bewegen das Material in Richtung und durch die Schlitze der zentralen Säule, die von den horizontalen flachen Ringen gebildet wird. Dieses bewährte System sorgt dafür, dass kohäsives Material ungehindert durch den offenen Kanal in der zentralen Säule nach unten fließen kann.

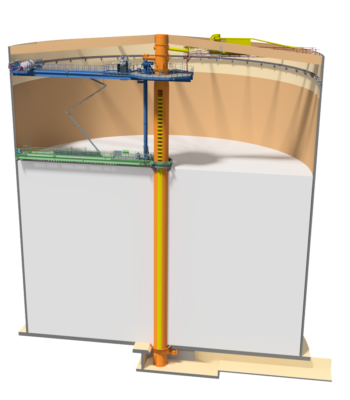

Funktionsprinzip: Verschluss-Säule

Das Schüttgut wird von oben über ein Befüllungsband und eine Ladeschurre in das Silo gebracht. Während der Befüllung verteilt der Verteilerrahmen das Material über die Oberfläche im Silo. Für die Entnahme ist die Rollladensäule so programmiert, dass sie sich mit einer kontrollierten Geschwindigkeit öffnet und schließt. Wenn Sie nur die Klappen an der Oberfläche der gelagerten Masse öffnen, kann das Material, das durch den Verteilerrahmen in Richtung der zentralen Säule bewegt wird, in die Rollladensäule gelangen. Mit fortschreitender Entnahme bestimmt die Höhe des Verteilerrahmens das korrekte Öffnen und Schließen der Klappen in der Säule.

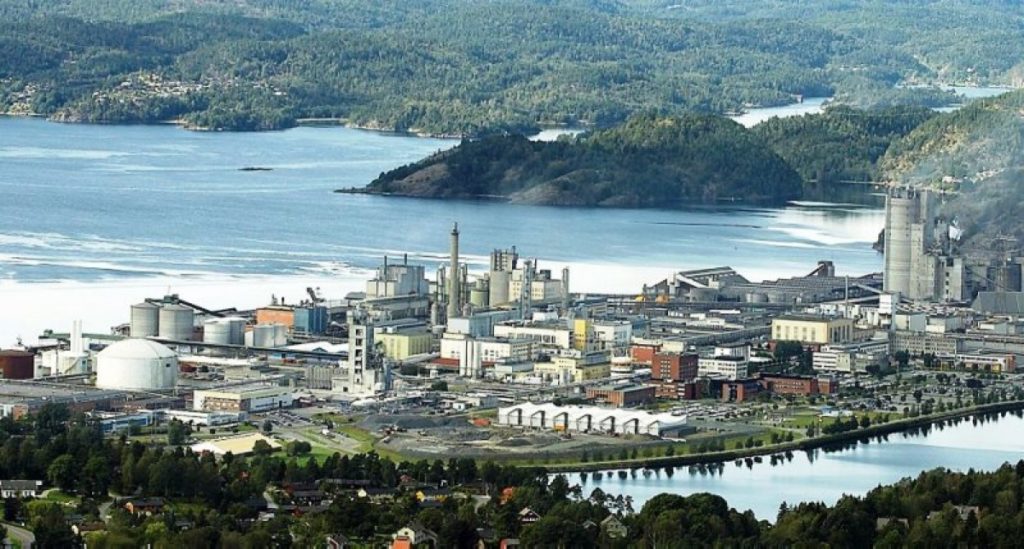

Fallstudie - Yara Porsgrunn

Die vollautomatischen Eurosilos sind so konzipiert, dass sie die Arbeitsabläufe in der chemischen Industrie rund um die Uhr unterbrechungsfrei unterstützen. Unser jüngstes Projekt war ein 20.000 m3 Eurosilo für Calciumnitrat in der Düngemittelfabrik von Yara Porsgrunn in Norwegen. Die Düngemittelanlage am Produktionsstandort wurde aufgerüstet, um die Produktionskapazität zu erweitern. ESI Eurosilo wurde mit der Planung und dem Bau eines Eurosilos beauftragt, das die Lagerung von 20.000 m3 Kalziumnitrat ermöglicht. Ihr Kommentar: „Im Vergleich zu den bestehenden Silos kann die Beschickung und Entleerung genauer gehandhabt werden. Dies gewährleistet einen ununterbrochenen Prozess, der durch den automatisierten Verteiler gesteuert wird, was zu einer erhöhten Produktivität und erheblichen Kosteneinsparungen führt.“

Kontaktieren Sie uns

Wenn Sie Fragen, Kommentare oder Anregungen haben, können Sie sich gerne an uns wenden. Füllen Sie unser Kontaktformular aus, und wir werden uns so schnell wie möglich bei Ihnen melden. Ihre Anfragen sind uns wichtig, und wir freuen uns darauf, Ihnen zu helfen.