Conversión a mediana edad

- Gran capacidad de almacenamiento

- Ahorro de espacio valioso

- Seguro para el medio ambiente

- Totalmente automatizado

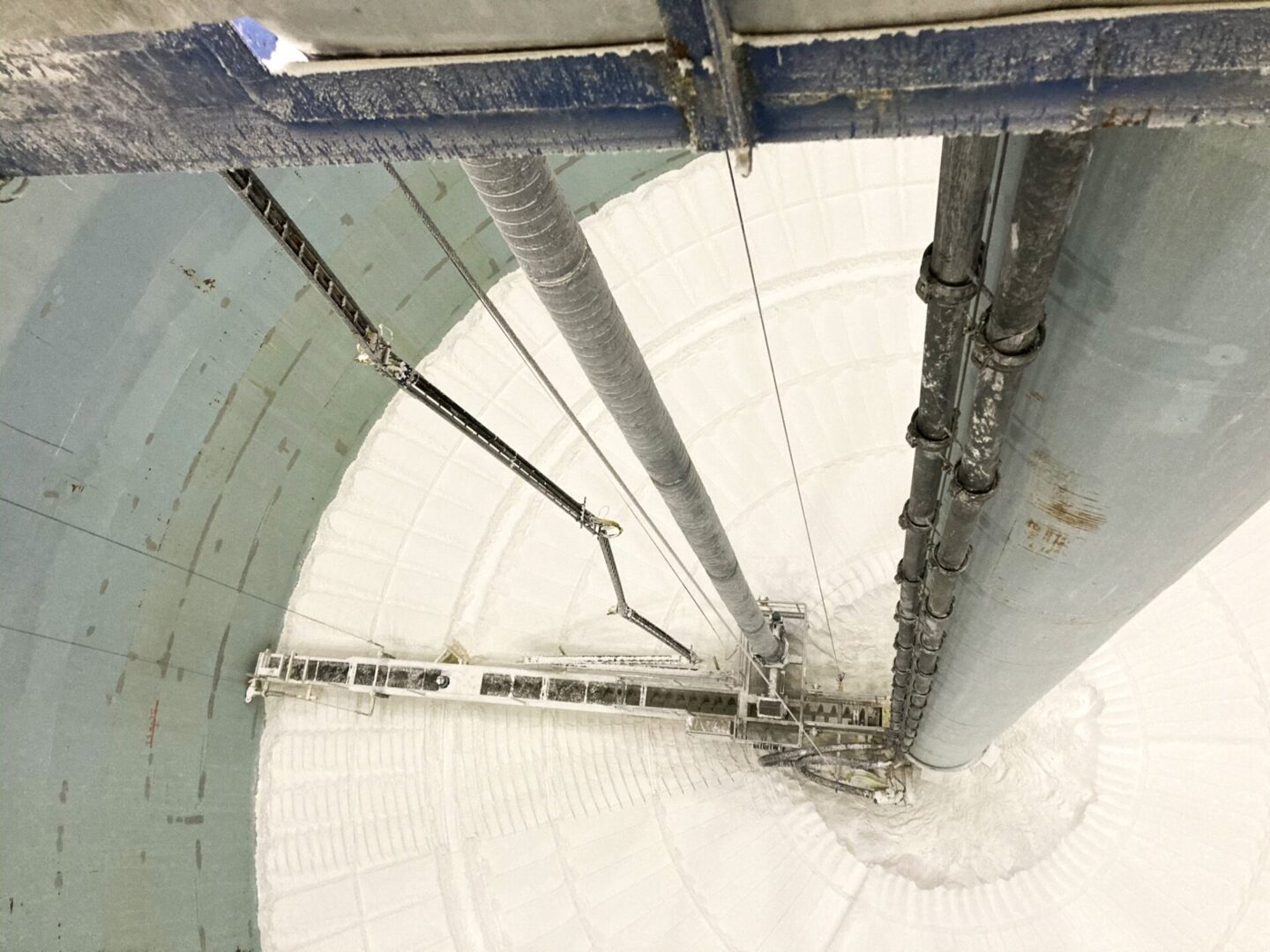

Mediante una reconversión a mitad de vida, puedes actualizar y mejorar los equipos de silos antiguos de acuerdo con las normas y técnicas actuales. Por supuesto, un silo nuevo superará a un sistema antiguo construido hace décadas. Sin embargo, en lugar de construir un sistema de silo completamente nuevo, podemos realizar una serie de actualizaciones y modificaciones que mejorarán el rendimiento y la seguridad, al tiempo que ahorran costes operativos.

Rendimiento mejorado

La conversión a media vida resuelve muchos inconvenientes y soluciones existentes a la vez. El resultado de una conversión a media vida es menos averías y menos tiempo de inactividad, así como un funcionamiento y control mejorados y más cómodos. También puedes centrarte en un mantenimiento preventivo bien planificado, en lugar de interrumpir el flujo logístico debido al mantenimiento correctivo. Las actualizaciones o mejoras adecuadas harán que cumplas las últimas normativas de seguridad, al tiempo que ahorras costes anuales con un menor coste total de propiedad.

Primero comprueba, luego planifica

El primer paso es inspeccionar y analizar el estado actual. Basándonos en las peticiones, requisitos e inspección, te ofreceremos un plan y una propuesta fundados. En estrecha colaboración con tu personal, podemos ejecutar las mejoras y modificaciones acordadas. Esto va desde el cumplimiento de los requisitos ATEX, como la sustitución de motores eléctricos e instrumentos por tipos con certificación ATEX, hasta mejoras de rendimiento mediante lubricación automática, accionamientos giratorios mejorados, reducción del polvo y muchas otras cosas.

Contacta con nosotros

No dudes en ponerte en contacto con nosotros si tienes alguna pregunta, comentario u opinión. Rellena nuestro formulario de contacto y nos pondremos en contacto contigo lo antes posible. Tus consultas son importantes para nosotros, y esperamos poder ayudarte.